SLS Plastic 3D Printing

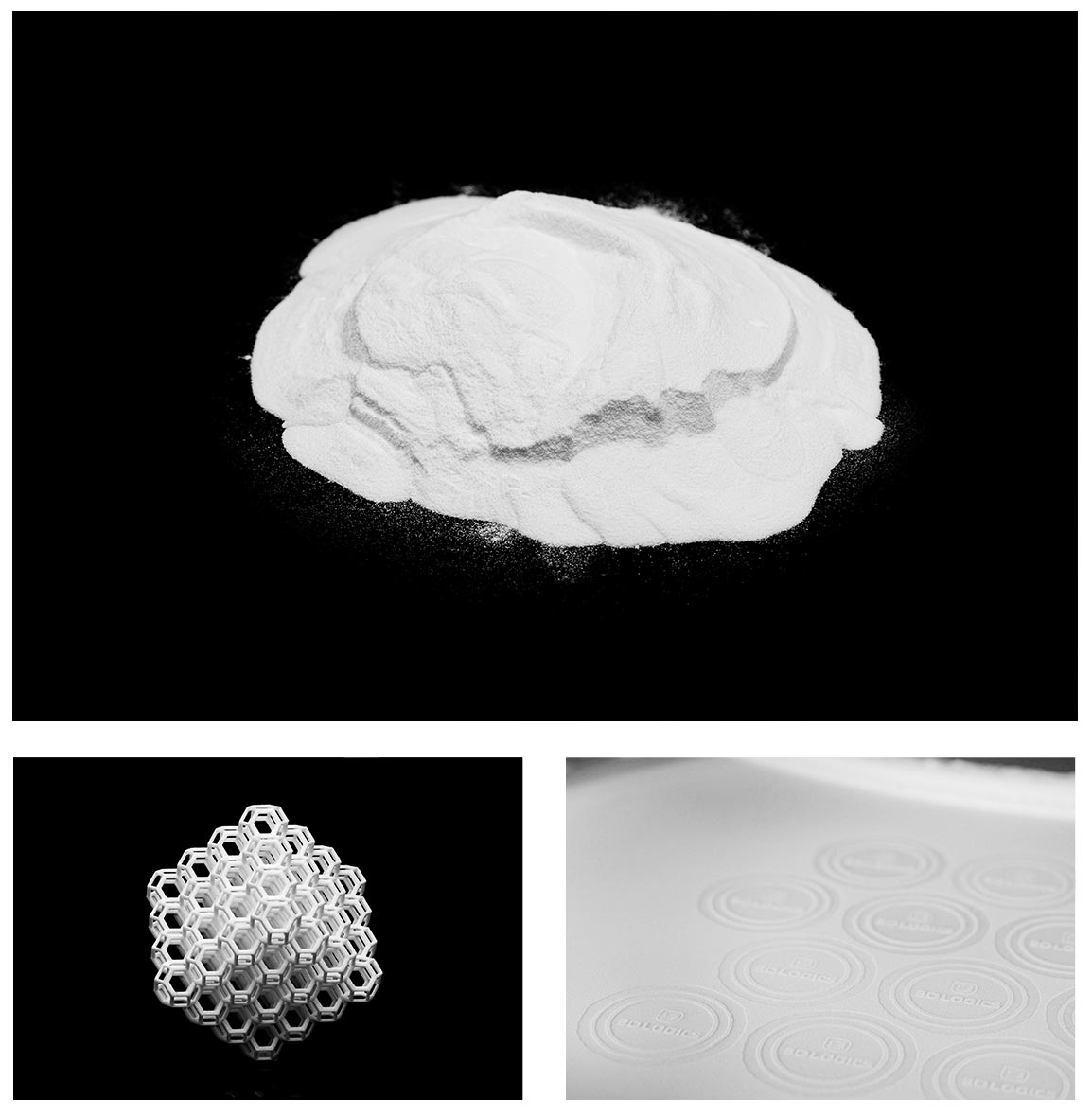

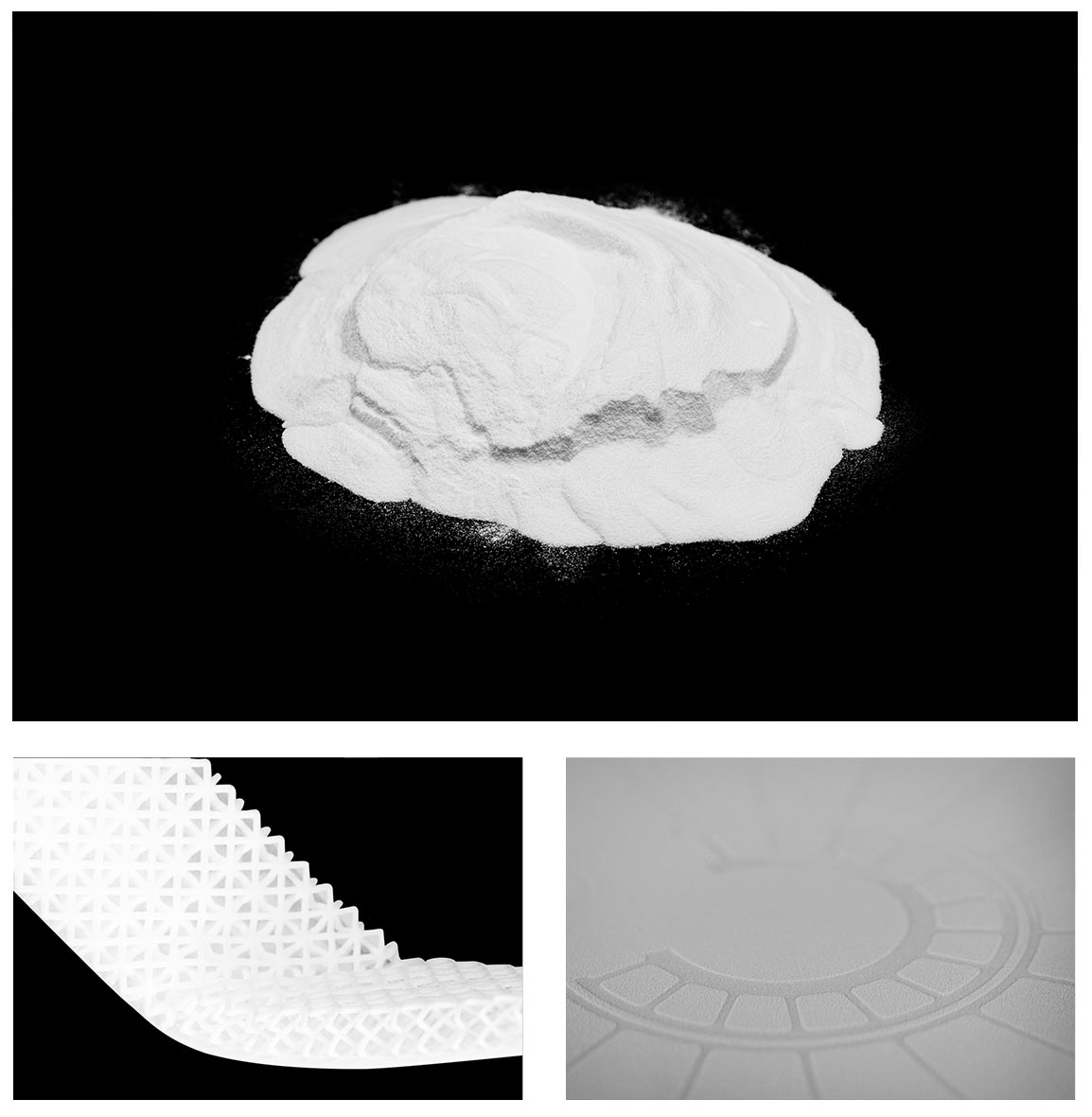

Selective Laser Sintering (SLS) is an industrial Additive Manufacturing process where plastic powder is melted by a precision laser, layer upon layer, to create an accurate three-dimensional polymer part.

About us Get a quote

Advantages of SLS

SLS 3D printing allows for the fabrication of complex parts that, in the past, have been impossible or cost prohibitive to produce through traditional manufacturing methods. We use a strong and durable Nylon polymer that is suitable for a wide variety of industries and applications and is also FDA approved for medical use. At 3D Logics we utilize the most advanced SLS 3D printing equipment to provide you with Additive Manufacturing solutions.

Production and Prototyping

Precision plastic parts to meet the demands of both production and prototyping

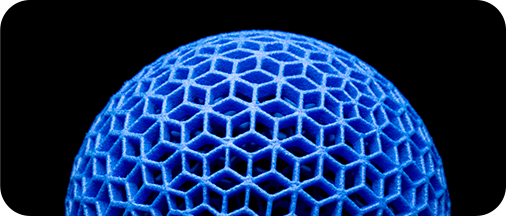

Complex Geometries

The SLS process allows for intricate design details not possible with other 3D printing technologies or traditional manufacturing methods

Durable + Strong

High strength Nylon meets the requirements of medical and industrial applications

EOS P110 Velocis Polymer 3D Printer

Selective Laser Sintering

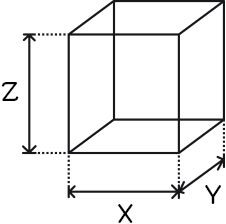

The EOS P110 Velocis is the industry standard for 3D printing of high-quality plastic parts. With a building volume of 200 × 250 × 330 mm, the EOS P110 Velocis allows for a fast, cost-effective, and reliable production process. The systems precision 40-watt fiber laser provides excellent detail resolution and part-to-part reliability and consistency.

Download Datasheet| What is plastic 3D printing |

| Build Size: | |||||

| 200 | X | 250 | X | 330 | MM |

| X | Y | Z | |||

| 7.87 | X | 9.84 | X | 12.99 | IN |

| X | Y | Z |

3D Printing Polymers

Nylon

Nylon is the most common polymer used for SLS 3D printing. Its well-balanced material properties make it a great choice for many applications.

Properties

- Great multi-purpose material

- High strength, stiffness, and abrasion resistance

- Good chemical resistance

- Maintains strength and shape over time

- High part detail resolution

- Multiple finishing opportunities (surface finishing, vibratory smoothing, coloring, and more)

- Bio compatible according to EN ISO 10993-1 and USP/level VI/121 °C

- Approved for food contact in compliance with the EU Plastics Directive 2002/72/EC

Applications

- Fully functional plastic parts

- Medical applications (i.e. prostheses, surgical guides, dental appliances)

- Suitable replacement for injection molded parts

- Moveable part connections possible

- Great for a wide variety of industries and applications

Download Datasheet

Other Polymers

There are many polymers available for the SLS 3D printing process. 3D Logics has experience printing other polymer powder blends for customer-specific projects or requirements. Please contact us if you have a specific need for other polymer materials or blends.

Polymer Alternatives

- Glass-filled Nylon

- Carbon-filled Nylon

- Flexible TPU

Download Datasheet

| Design Guidelines | |||||

|---|---|---|---|---|---|

|

Standard

Accuracy ± 0.1 - 0.2mm

|

Minimum

Thickness 0.6mm

|

Minimum

Details 0.3mm

|

Minimum

Clearance 0.5mm

|

Interlocking

Parts |

Support

Structures |

Discover how we turn raw materials into high-value products

We don’t just 3D print parts, we offer full in-house post processing and finishing to provide you with a complete Additive Manufacturing solution. See what we have to offer.

Our Finishing Capabilities

- DyeMansion PowerShot C – Cleaning and Depowdering

- DyeMansion PowerShot S - Surfacing

- DyeMansion DM60 – DeepDye Coloring

- Barrel Finishing

- Disc Finishing

- Vibratory Tumbling Finishing

- 3D Scanning

- Ultrasonic Cleaning